Activated alumina desiccant is a key player in moisture control. This material is highly effective in adsorbing water from gases and liquids.

Understanding how it works and its benefits can help you in various applications. Activated alumina desiccant is used in air dryers, water treatment, and gas purification. This versatile product is known for its high surface area and porosity, making it excellent at trapping water molecules.

Industries rely on it to protect equipment and maintain product quality. In this blog post, we will explore the advantages of using activated alumina desiccant and its various applications. Whether you are in manufacturing, healthcare, or another sector, this material can be crucial for your operations. Let’s dive into the details of activated alumina desiccant and its practical uses.

What Is Activated Alumina?

Activated Alumina Desiccant is a highly effective material used for drying air and gases. Its main job is to absorb moisture, keeping environments dry and free from humidity. But what is Activated Alumina?

Composition

Activated Alumina is made from aluminum oxide. This material is processed to create a porous structure. The pores help in absorbing water and other substances. Here are some key points about its composition:

- Aluminum Oxide (Al2O3): This is the primary material in Activated Alumina.

- Porous Structure: The material is treated to develop many small pores. These pores increase the surface area, allowing it to absorb more moisture.

- High Purity: Activated Alumina is typically over 90% pure aluminum oxide. This purity ensures its effectiveness in various applications.

Below is a table summarizing the composition of Activated Alumina:

| Component | Percentage |

|---|---|

| Aluminum Oxide (Al2O3) | 90% – 99% |

| Other Oxides | 1% – 10% |

Properties

Activated Alumina has several important properties that make it ideal for drying and purification. Here are some of its key properties:

- High Surface Area: The porous structure gives it a large surface area. This increases its ability to absorb moisture.

- Thermal Stability: It can withstand high temperatures without breaking down. This makes it useful in many industrial applications.

- Regenerable: Activated Alumina can be reused. Heating it removes the absorbed moisture, making it ready for use again.

- Non-Toxic: It is safe for use in food and water purification. It does not release harmful substances.

Here is a summary of the key properties of Activated Alumina:

| Property | Details |

|---|---|

| Surface Area | 200 – 300 m2/g |

| Thermal Stability | Up to 600°C |

| Reusability | Yes, through regeneration |

| Toxicity | Non-toxic |

These properties make Activated Alumina a versatile and effective desiccant. It is used in many industries, from air drying to water purification.

Credit: sse.co.th

How Activated Alumina Works

Activated Alumina Desiccant is a highly porous and adsorbent form of aluminum oxide. It’s used to remove moisture from various gases and liquids, ensuring optimal performance in various applications. Let’s dive into how activated alumina works to understand its unique properties and capabilities.

Adsorption Process

Activated alumina operates through a process known as adsorption. This is different from absorption, where substances are taken into the bulk of the material. In adsorption, molecules adhere to the surface.

Here’s how the adsorption process works:

- Surface Area: Activated alumina has a vast surface area. This provides numerous sites for moisture and impurities to attach.

- Pore Structure: It features a network of pores. These pores trap water molecules, removing them from the gas or liquid stream.

- Polarity: The surface of activated alumina is polar. This polarity attracts water molecules, which are also polar.

The efficiency of the adsorption process depends on several factors:

| Factor | Impact |

|---|---|

| Temperature | Higher temperatures can reduce adsorption efficiency. |

| Pressure | Higher pressures can increase adsorption efficiency. |

| Flow Rate | Slower flow rates allow more time for adsorption. |

Moisture Absorption

Activated alumina is highly effective in moisture absorption. It can absorb water from gases and liquids, making it an essential tool in various industries.

Here’s how moisture absorption works:

- Capillary Action: Water molecules are drawn into the pores of the activated alumina.

- Hydrophilic Nature: The material naturally attracts water due to its chemical properties.

- Physical Trapping: Water molecules get physically trapped within the pore structure.

Factors affecting moisture absorption include:

- Humidity Levels: Higher humidity leads to more moisture absorption.

- Contact Time: Longer exposure increases absorption efficiency.

- Regeneration: The ability to reuse activated alumina after drying it out.

Activated alumina is used in:

- Air Drying: Removing moisture from compressed air systems.

- Water Treatment: Purifying water by removing impurities and moisture.

- Gas Drying: Ensuring gas streams are free from moisture.

Its ability to absorb moisture ensures that systems function correctly, preventing corrosion and other issues caused by water presence.

Applications Of Activated Alumina

Activated Alumina Desiccant is a highly porous material that is used to adsorb water and other impurities from gases and liquids. Its applications are vast and varied, making it a valuable asset in both industrial and household settings. This blog post explores the diverse applications of Activated Alumina and how it benefits different sectors.

Industrial Uses

Activated Alumina Desiccant is widely utilized in industrial settings due to its exceptional adsorption properties. It plays a crucial role in various processes, ensuring the removal of moisture and impurities. Here are some key industrial applications:

- Air and Gas Drying: Activated Alumina is essential in drying compressed air and industrial gases. It removes moisture, which can cause equipment corrosion and inefficiencies.

- Water Treatment: It is used to remove fluoride, arsenic, and selenium from water, making it safe for consumption and industrial use.

- Petrochemical Industry: Activated Alumina desiccant is used to purify gases and liquids in the petrochemical industry, ensuring high product quality.

- Hydrogen Peroxide Production: It acts as a catalyst in the production of hydrogen peroxide, enhancing efficiency and yield.

The following table summarizes the industrial uses of Activated Alumina Desiccant:

| Application | Description |

|---|---|

| Air and Gas Drying | Removes moisture from compressed air and gases |

| Water Treatment | Eliminates contaminants like fluoride and arsenic |

| Petrochemical Purification | Purifies gases and liquids for better quality |

| Hydrogen Peroxide Production | Acts as a catalyst for efficient production |

Household Uses

While Activated Alumina Desiccant is known for its industrial applications, it also has practical household uses. It helps improve the quality of everyday life by keeping environments dry and safe. Here are some common household applications:

- Dehumidifiers: Activated Alumina is used in home dehumidifiers to reduce humidity levels. This prevents mold growth and protects furniture.

- Water Filtration: It is a key component in home water filtration systems. It removes contaminants like fluoride, making drinking water safer.

- Cat Litter: Activated Alumina is sometimes used in cat litter to control odor and absorb moisture.

- Food Storage: Small packets of Activated Alumina are used in food packaging to keep products dry and extend shelf life.

Below is a table that highlights the household uses of Activated Alumina Desiccant:

| Application | Description |

|---|---|

| Dehumidifiers | Reduces humidity to prevent mold |

| Water Filtration | Removes harmful contaminants from drinking water |

| Cat Litter | Controls odor and absorbs moisture |

| Food Storage | Keeps food products dry and extends shelf life |

Credit: wisesorbent.com

Advantages Of Using Activated Alumina

Activated Alumina Desiccant is a highly effective drying agent used in various industrial applications. It is known for its remarkable moisture absorption and chemical stability. The advantages of using Activated Alumina are numerous, making it a preferred choice in many sectors. Below, we delve into some key benefits.

High Efficiency

Activated Alumina Desiccant boasts high efficiency in moisture absorption. This makes it an excellent choice for applications requiring stringent humidity control.

Its hygroscopic properties allow it to attract and hold water molecules, which enhances its desiccant performance. Here’s a closer look at its efficiency:

- High Adsorption Capacity: Activated Alumina can adsorb up to 20% of its weight in water.

- Fast Moisture Absorption: The desiccant material quickly absorbs moisture, ensuring dry conditions.

- Chemical Stability: It remains stable in various chemical environments, making it suitable for diverse industrial applications.

In addition to these points, the efficiency of Activated Alumina can be represented in the table below:

| Property | Efficiency |

|---|---|

| Adsorption Capacity | High |

| Moisture Absorption Rate | Fast |

| Chemical Stability | Excellent |

These properties make Activated Alumina a reliable choice for maintaining dry and stable conditions in sensitive environments.

Regeneration Capability

One of the standout features of Activated Alumina Desiccant is its regeneration capability. This allows it to be reused, reducing costs and promoting sustainability.

Thermal regeneration is a common method used to restore the desiccant material’s effectiveness. Here’s how it works:

- The saturated desiccant is exposed to high temperatures.

- The heat drives off the absorbed moisture.

- The desiccant is cooled and ready for reuse.

Some key benefits of this process include:

- Cost Savings: Reusing the desiccant reduces the need for frequent replacements.

- Sustainability: Regenerating the desiccant minimizes waste and environmental impact.

- Consistent Performance: The desiccant retains its adsorption capacity after each regeneration cycle.

This makes Activated Alumina a durable and eco-friendly choice for industries that require reliable drying agents.

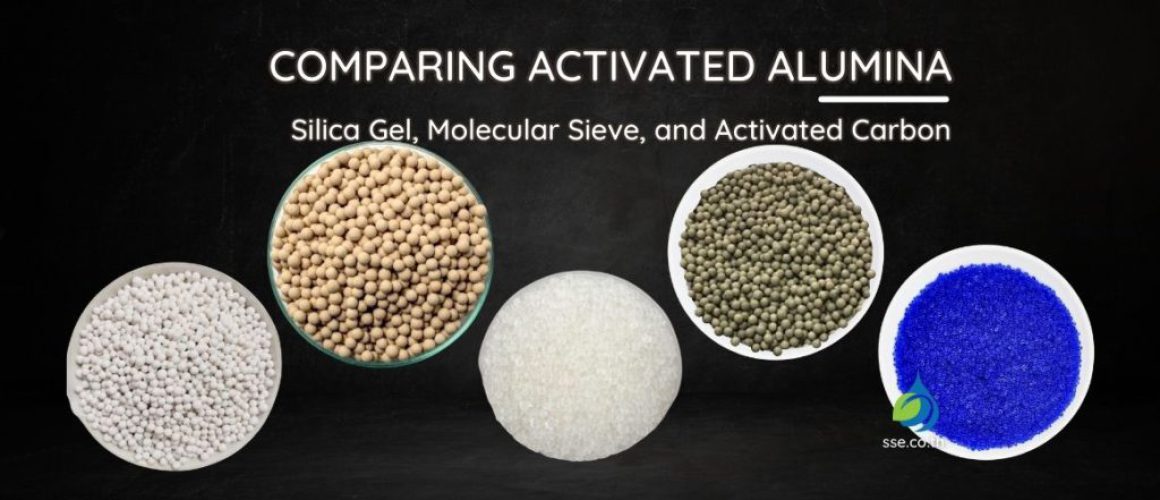

Activated Alumina Vs Other Desiccants

Activated Alumina Desiccant is a highly effective material used to remove moisture from gases and liquids. It’s widely used in various industries due to its high adsorption capacity and durability. In this section, we will compare Activated Alumina with other common desiccants to help you understand its advantages.

Silica Gel Comparison

Silica Gel is another popular desiccant used for moisture control. It’s known for its ability to absorb a significant amount of water vapor. However, there are several differences between Silica Gel and Activated Alumina.

Advantages of Silica Gel:

- High absorption capacity

- Non-toxic and safe to use

- Widely available and cost-effective

Advantages of Activated Alumina:

- Higher adsorption capacity at higher temperatures

- More durable and long-lasting

- Works well in both acidic and basic environments

Comparison Table:

| Feature | Silica Gel | Activated Alumina |

|---|---|---|

| Adsorption Capacity | High | Higher at high temperatures |

| Durability | Moderate | High |

| Temperature Range | Limited | Wide |

| Environmental Suitability | Neutral | Acidic and Basic |

Calcium Chloride Comparison

Calcium Chloride is another commonly used desiccant. It’s particularly effective in high humidity environments. Here are some comparisons between Calcium Chloride and Activated Alumina.

Advantages of Calcium Chloride:

- High moisture absorption

- Cost-effective

- Easy to use

Advantages of Activated Alumina:

- Does not dissolve in water, unlike Calcium Chloride

- More suitable for high-temperature applications

- Reusable after regeneration

Comparison Table:

| Feature | Calcium Chloride | Activated Alumina |

|---|---|---|

| Moisture Absorption | Very High | High |

| Water Solubility | Soluble | Insoluble |

| Temperature Range | Low to Moderate | Wide |

| Regeneration | Not Possible | Possible |

Comparison Table With Other Desiccants

Here is a comparison table to help you understand how Activated Alumina stands against other common desiccants like Silica Gel and Calcium Chloride.

Comparison Table:

| Desiccant | Adsorption Capacity | Durability | Temperature Range | Regeneration |

|---|---|---|---|---|

| Silica Gel | High | Moderate | Limited | Possible |

| Calcium Chloride | Very High | Low | Low to Moderate | Not Possible |

| Activated Alumina | High | High | Wide | Possible |

Credit: www.agmcontainer.com

Regeneration Process

Activated alumina desiccant is a highly effective material used to remove moisture from the air and gases. Over time, the desiccant absorbs moisture and becomes saturated, losing its efficiency. To restore its effectiveness, the desiccant must undergo a regeneration process. This process involves removing the accumulated moisture, allowing the activated alumina to be reused for further moisture adsorption.

Methods

Several methods can be employed to regenerate activated alumina desiccant. Each method varies in complexity and efficiency.

Thermal Regeneration: This is the most common method. The desiccant is heated to high temperatures, typically between 175°C and 260°C. Heating evaporates the absorbed moisture, restoring the desiccant’s capacity. Here’s a breakdown of the steps involved:

- Pre-heating: Gradually increase the temperature to avoid thermal shock.

- Heating: Maintain the temperature within the specified range.

- Cooling: Allow the desiccant to cool down before reuse.

Pressure Swing Adsorption (PSA): This method uses pressure changes to regenerate the desiccant. The desiccant is alternated between high and low pressures. At low pressure, the desiccant releases the absorbed moisture.

Vacuum Regeneration: This method involves placing the desiccant in a vacuum chamber. The reduced pressure allows the moisture to evaporate at lower temperatures. This method is energy-efficient and suitable for sensitive applications.

A comparison of these methods is presented in the table below:

| Method | Temperature Range | Energy Efficiency | Application Suitability |

|---|---|---|---|

| Thermal Regeneration | 175°C – 260°C | Moderate | General |

| Pressure Swing Adsorption | Ambient | High | Industrial |

| Vacuum Regeneration | Lower than thermal | High | Sensitive |

Frequency

The frequency of regeneration depends on several factors. These include the operating conditions and the environment in which the desiccant is used.

Operating Conditions: The frequency of regeneration increases with higher humidity levels. In humid environments, the desiccant absorbs moisture quickly, requiring more frequent regeneration. In contrast, in dry conditions, the desiccant takes longer to reach saturation.

Usage Patterns: Continuous operation systems need more frequent regeneration. Systems with intermittent use may require less frequent regeneration.

Manufacturer Recommendations: Follow the manufacturer’s guidelines for optimal performance. These guidelines provide the recommended regeneration intervals based on typical usage scenarios.

Here’s a quick reference guide for regeneration frequency:

- High Humidity: Regenerate every 48 hours.

- Moderate Humidity: Regenerate every 72 hours.

- Low Humidity: Regenerate every 96 hours.

Regular monitoring is crucial. Check the desiccant’s performance periodically. Use moisture indicators to assess the saturation level. If performance drops, it’s time for regeneration.

Adhering to the recommended regeneration schedule ensures the longevity and efficiency of the activated alumina desiccant.

Safety And Handling

Activated alumina desiccant is widely used for drying air and gases. It plays a crucial role in preventing moisture-related damage. While its benefits are extensive, understanding its safety and handling is essential. Proper storage and disposal ensure the desiccant remains effective and safe for use.

Storage Guidelines

Storing activated alumina desiccant correctly ensures its longevity and effectiveness. Follow these storage guidelines to maintain its quality:

- Keep in a dry place: Store the desiccant in a dry, cool area. Moisture can reduce its efficiency.

- Avoid direct sunlight: Exposure to direct sunlight can degrade the material over time.

- Use airtight containers: Seal the desiccant in airtight containers. This prevents moisture absorption from the surrounding environment.

- Label containers: Clearly label all containers with the contents and date of storage. This helps in tracking and managing inventory effectively.

- Avoid contamination: Ensure the storage area is clean. Contaminants can affect the desiccant’s performance.

Here is a simple table to summarize the storage guidelines:

| Guideline | Details |

|---|---|

| Dry Place | Store in a cool, dry area |

| Direct Sunlight | Avoid exposure |

| Airtight Containers | Use sealed containers |

| Labeling | Label with contents and storage date |

| Contamination | Keep storage area clean |

Disposal Recommendations

Proper disposal of activated alumina desiccant is crucial for environmental safety. Follow these recommendations to dispose of it responsibly:

- Check local regulations: Always check local disposal regulations. Guidelines may vary by region.

- Use designated disposal sites: Dispose of the desiccant at designated hazardous waste disposal sites. These sites are equipped to handle such materials safely.

- Avoid water sources: Never dispose of the desiccant near water sources. It can contaminate water and harm aquatic life.

- Contain properly: Ensure the desiccant is sealed in a sturdy, leak-proof container. This prevents any leakage during transportation.

- Inform disposal personnel: Inform the disposal personnel about the contents of the waste. Clear labeling and communication are key.

Here’s a breakdown of the disposal steps:

| Step | Action |

|---|---|

| 1 | Check local regulations |

| 2 | Use designated disposal sites |

| 3 | Avoid water sources |

| 4 | Contain properly |

| 5 | Inform disposal personnel |

By following these guidelines, you ensure the safe handling and disposal of activated alumina desiccant, protecting both its effectiveness and the environment.

Future Trends In Desiccants

Activated alumina desiccant is a powerful drying agent used in various industries. It absorbs moisture and keeps products free from humidity. As technology evolves, the future of desiccants is also changing. These advancements will bring new materials and a focus on sustainability. Let’s explore these future trends in detail.

Innovative Materials

New materials are being developed for desiccants. These materials aim to improve performance and efficiency. Some of these innovative materials include:

- Silica Gel: Known for its high moisture-absorbing capability.

- Molecular Sieves: Effective for separating molecules based on size.

- Clay Desiccants: Natural and cost-effective option.

Each of these materials has unique properties. For example, silica gel can absorb up to 40% of its weight in moisture. Molecular sieves offer precise control over the size of molecules they absorb. Clay desiccants are environmentally friendly and easy to obtain.

Here’s a comparison table of these materials:

| Material | Moisture Absorption | Cost | Environmental Impact |

|---|---|---|---|

| Silica Gel | High | Moderate | Low |

| Molecular Sieves | Very High | High | Moderate |

| Clay Desiccants | Moderate | Low | Very Low |

These advancements in materials promise better efficiency and a variety of options for different needs. Choosing the right desiccant can enhance product longevity and performance.

Sustainability Efforts

The future of desiccants also includes a strong focus on sustainability. Companies are exploring eco-friendly options. Reducing environmental impact is a key goal. Some of the sustainability efforts include:

- Recyclable Desiccants: Designed to be reused multiple times.

- Biodegradable Options: Made from natural materials that decompose easily.

- Energy-Efficient Production: Lowering energy use during manufacturing.

Recyclable desiccants can be recharged by heating, making them cost-effective. Biodegradable desiccants help reduce waste. Energy-efficient production processes also cut down on emissions and resource use.

Here’s a brief overview of these sustainability initiatives:

| Initiative | Benefit | Example |

|---|---|---|

| Recyclable Desiccants | Cost-effective and less waste | Heating to recharge |

| Biodegradable Options | Reduces landfill waste | Natural clay or plant-based materials |

| Energy-Efficient Production | Lower carbon footprint | Advanced manufacturing techniques |

These sustainability efforts are crucial for the future. They ensure that desiccants are not only effective but also environmentally responsible. This balance is essential for long-term success and environmental health.

Frequently Asked Questions

What Is Activated Alumina Desiccant?

Activated alumina desiccant is a highly porous material. It is used to adsorb moisture from gases and liquids. It is effective in drying and purification processes.

How Does Activated Alumina Work?

Activated alumina works by adsorbing water molecules. Its porous structure traps moisture, preventing it from passing through. This makes it ideal for drying applications.

What Are The Uses Of Activated Alumina?

Activated alumina is used in water purification, air drying, and gas drying. It is also used in the petrochemical industry and for fluoride removal.

Is Activated Alumina Reusable?

Yes, activated alumina can be regenerated. It can be reused by heating to remove the adsorbed moisture. This makes it cost-effective.

Conclusion

Activated alumina desiccant offers many benefits. It efficiently removes moisture from air and gases. This leads to better performance and longer life of equipment. Industries like water treatment and gas drying rely on it. It’s cost-effective and durable. Using activated alumina ensures a drier environment.

This helps prevent damage and corrosion. Consider it for your moisture control needs. It’s a smart and practical choice.