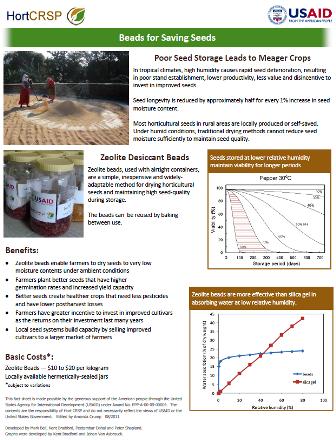

Zeolite and silica gel are two popular desiccants. Both are used to control moisture.

Understanding the differences between zeolite and silica gel helps you choose the right one. Zeolite is a natural mineral with unique properties. Silica gel, on the other hand, is a synthetic material made from silicon dioxide. Each has its own strengths and weaknesses.

Comparing these two can help you make an informed decision. This guide will explore their benefits, uses, and key differences. By the end, you’ll know which is better for your needs. Let’s dive into the details of zeolite vs. Silica gel.

Introduction To Zeolite

Zeolite and silica gel are both widely used materials. They are known for their ability to absorb moisture. Zeolite is a mineral with a unique structure. It is often used in water purification. Silica gel, on the other hand, is a granular, porous form of silicon dioxide. It is commonly used as a desiccant. Understanding the differences between these two materials can help in choosing the right one for specific needs.

Natural Vs Synthetic

Zeolite can be found in nature or made synthetically. Natural zeolites are formed from volcanic rocks and ash. They are mined from various places around the world. Synthetic zeolites are created in laboratories. They are designed to have specific properties for industrial use. The choice between natural and synthetic depends on the application.

Natural zeolites have the following characteristics:

- Environmentally friendly

- Lower cost

- Less uniform in structure

Synthetic zeolites offer these advantages:

- Highly uniform structure

- Customizable properties

- Higher purity

Silica gel is usually synthetic. It is produced from sodium silicate. Silica gel is used in various industries due to its high absorption capacity. It is not found in nature in the form used industrially. The choice between natural and synthetic materials can impact performance and cost.

Common Uses

Zeolite and silica gel serve different purposes. Zeolite is often used in water treatment. It removes heavy metals and softens water. It is also used in agriculture to improve soil quality. In the medical field, zeolite is used for drug delivery and detoxification.

Common uses of zeolite include:

- Water purification

- Soil amendment

- Odor control

Silica gel is widely used as a desiccant. It keeps products dry by absorbing moisture. It is often found in packaging to protect electronics, food, and clothing. Silica gel is also used in chromatography for separating substances.

Common uses of silica gel include:

- Packaging desiccant

- Chromatography

- Humidity control

Both zeolite and silica gel have unique properties. Their uses vary across different industries. Understanding these properties can help in selecting the right material for specific applications.

Introduction To Silica Gel

Zeolite and Silica Gel are both important materials used for drying and purifying substances. Zeolite is a natural or synthetic mineral with a unique structure. Silica Gel, on the other hand, is a porous, granular form of silicon dioxide. Both have unique properties and applications in various industries. In this post, we will explore Silica Gel in detail. We will discuss its properties and how it is used in different industries.

Properties Of Silica Gel

Silica Gel has unique properties that make it useful in many applications. It is a porous and granular form of silicon dioxide. This means it has many tiny holes that can trap moisture and gases. Here are some important properties:

- High Surface Area: Silica Gel has a large surface area, allowing it to absorb more moisture.

- Non-Toxic: It is safe for use in food and pharmaceutical products.

- Chemically Inert: It does not react with other chemicals.

- Thermally Stable: Silica Gel can withstand high temperatures without breaking down.

- Reusable: It can be dried and reused multiple times.

Silica Gel is often seen as small beads or packets. These packets are placed in products to keep them dry. The beads change color when they absorb moisture, indicating they need to be replaced or dried out. This visual cue is very helpful in various applications.

Applications In Industry

Silica Gel is used in many industries due to its unique properties. Here are some common applications:

- Packaging: Used to keep products dry during shipping and storage. It prevents damage from moisture.

- Electronics: Placed in packaging to protect electronic components from moisture.

- Pharmaceuticals: Ensures medicines stay dry and effective. It is safe for use with food and drugs.

- Food Industry: Maintains the freshness of dry foods by absorbing moisture.

- Air Purification: Used in air filters to remove moisture and improve air quality.

Silica Gel is also used in laboratories for chromatography. This process separates different substances in a mixture. The gel’s high surface area and porous nature make it ideal for this purpose.

Chemical Composition

Zeolite and Silica Gel are two popular materials used for drying and purifying purposes. They have different chemical compositions and properties. Understanding these differences is important to choose the right one for your needs.

Zeolite Composition

Zeolite is a mineral with a unique structure. It is made of aluminosilicates. These are compounds of aluminum, silicon, and oxygen. The structure of Zeolite is a framework of tetrahedral units.

These units consist of:

- Aluminum (Al) atoms

- Silicon (Si) atoms

- Oxygen (O) atoms

This framework creates pores and channels. These are perfect for trapping molecules. Zeolites also have cation-exchange properties. This means they can exchange cations with their environment. Common cations in Zeolites are:

- Sodium (Na)

- Potassium (K)

- Calcium (Ca)

- Magnesium (Mg)

These properties make Zeolites useful in water purification, gas separation, and catalysis. They are also used in detergents to soften water.

Silica Gel Composition

Silica Gel is made from silicon dioxide (SiO2). It is a porous form of silica. This material is produced by polymerizing silicon compounds. The result is a solid, granular substance. Silica Gel has a high surface area. This allows it to adsorb a lot of moisture.

The composition of Silica Gel includes:

- Silicon (Si) atoms

- Oxygen (O) atoms

Silica Gel is often used in packaging to keep products dry. It is also used in electronics, pharmaceuticals, and food storage. Silica Gel is non-toxic and can be reused after drying. This makes it a cost-effective option for moisture control.

Both Zeolite and Silica Gel have their unique advantages. Choosing the right one depends on your specific needs.

Credit: digitalagrifarm.com

Adsorption Mechanisms

Zeolite and silica gel are two common materials used for adsorption. Adsorption is the process where molecules stick to the surface of a material. This process helps in various applications like drying, purifying, and filtering. Understanding how zeolite and silica gel work can help you decide which one to use for your needs.

Zeolite Adsorption

Zeolite is a porous material. It has a unique structure that makes it very effective for adsorption. Here are some key points about zeolite:

- Micro-porous structure: Zeolite has tiny pores, about the size of molecules.

- High surface area: These pores create a large surface area for adsorption.

- Selective adsorption: Zeolite can adsorb specific molecules while ignoring others.

This makes zeolite ideal for applications like:

- Gas separation: Zeolite can separate gases like oxygen and nitrogen.

- Water purification: It can remove ions and metals from water.

Zeolite’s performance depends on its type. Different zeolites have different pore sizes and structures. This affects what they can adsorb. Overall, zeolite is a versatile and powerful adsorbent.

Silica Gel Adsorption

Silica gel is another widely used adsorbent. It consists of small, hard pellets with a porous structure. Here are some important points about silica gel:

- High surface area: Silica gel has many pores, creating a large surface area.

- Moisture adsorption: It is highly effective at adsorbing water vapor.

- Non-toxic: Silica gel is safe and non-toxic, making it suitable for various uses.

Silica gel is commonly used in:

- Packaging: To keep products dry.

- Electronics: To prevent moisture damage.

Silica gel works well in environments with high humidity. It can adsorb a large amount of moisture quickly. This makes it a valuable tool for protecting sensitive items.

Water Absorption Capacity

Understanding the water absorption capacity of materials is essential for many applications. Two commonly used materials for this purpose are Zeolite and Silica Gel. Both have unique properties that make them suitable for different uses. This article will explore the water retention capabilities of these two materials.

Zeolite Water Retention

Zeolite is a mineral with a porous structure. This structure allows it to absorb and hold water efficiently. It is often used in agriculture, water purification, and air conditioning systems. Zeolite’s ability to retain water can be attributed to its unique composition.

Here are some key points about Zeolite’s water retention:

- Porous structure: The tiny holes in Zeolite can trap water molecules.

- High surface area: This increases its capacity to hold water.

- Chemical composition: Its natural minerals attract and hold water.

Zeolite can absorb up to 30% of its weight in water. This makes it an excellent choice for applications that require high water retention. For example, it is used in soil to help retain moisture for plants.

Silica Gel Water Retention

Silica Gel is another material known for its water absorption capabilities. It is commonly found in small packets inside product packaging to keep items dry. Silica Gel is made from silicon dioxide and has a high affinity for water.

Let’s look at some important aspects of Silica Gel’s water retention:

- High absorption rate: Silica Gel can absorb up to 40% of its weight in water.

- Reusable: It can be dried and used again multiple times.

- Versatile: Suitable for many uses like electronics, food packaging, and pharmaceuticals.

Silica Gel works by trapping water molecules in its tiny pores. This keeps the surrounding environment dry. It is not just effective but also easy to regenerate. Simply heat it to remove the absorbed water and it is ready to use again.

Regeneration And Reusability

Zeolite and silica gel are both popular desiccants used to control moisture. Both materials have unique properties and benefits. This blog post will explore how these desiccants can be regenerated and reused. Understanding their regeneration and reusability can help in making an informed choice.

Zeolite Regeneration

Zeolite is a crystalline material known for its ability to absorb water. This makes it ideal for moisture control. One of the key benefits of zeolite is its regeneration capability. Regenerating zeolite involves heating it to remove absorbed water. This process is straightforward and effective.

To regenerate zeolite, follow these steps:

- Preheat an oven to 250°C (482°F).

- Spread the zeolite evenly on a baking tray.

- Place the tray in the oven for 2-3 hours.

- Allow the zeolite to cool before reuse.

Heating zeolite at high temperatures ensures it releases all the absorbed moisture. This makes it nearly as good as new. Zeolite can be regenerated multiple times without losing its efficiency. This makes it a cost-effective choice for long-term use.

Silica Gel Reusability

Silica gel is another popular desiccant. It is known for its high moisture absorption capacity. Reusing silica gel is also possible, but the process is slightly different. Silica gel beads change color when they are saturated with moisture. This indicates that they need to be dried.

To reuse silica gel, follow these steps:

- Preheat an oven to 120°C (250°F).

- Spread the silica gel beads on a baking sheet.

- Place the sheet in the oven for 1-2 hours.

- Allow the beads to cool before reuse.

Silica gel can be reused multiple times as well. However, the beads may become less effective over time. This is because the drying process can cause the beads to break down slowly. Despite this, silica gel remains an excellent choice for moisture control.

Environmental Impact

In the world of moisture control, both zeolite and silica gel are popular choices. Understanding their environmental impact is important. This helps in making an informed decision. Each material has its own benefits and concerns. Let’s explore the sustainability of zeolite and the concerns related to silica gel.

Zeolite Sustainability

Zeolite is a natural mineral. It is found abundantly in the Earth’s crust. This makes zeolite highly sustainable. Here are some key points:

- Natural and abundant: Zeolite is not manufactured. It is mined from the earth.

- Low environmental impact: The process of mining zeolite is less harmful to the environment.

- Reusable: Zeolite can be regenerated and reused multiple times.

These factors make zeolite a green choice. It is not only effective but also eco-friendly.

Silica Gel Concerns

Silica gel is widely used for moisture control. But it has some environmental concerns. Here are some important issues:

- Non-renewable: Silica gel is made from silicon dioxide. This is not a renewable resource.

- Manufacturing impact: The production of silica gel involves chemical processes. These processes can be harmful to the environment.

- Disposal issues: Silica gel is not biodegradable. It can contribute to landfill waste.

These factors make silica gel a less sustainable option. While effective, it has a higher environmental cost.

Credit: agro.biodiver.se

Cost Comparison

Zeolite and Silica Gel are popular materials used for drying, purifying, and separating substances. They are widely used in industries like pharmaceuticals, food packaging, and petrochemicals. Understanding the cost difference between Zeolite and Silica Gel can help businesses make informed decisions. Let’s compare the pricing of both materials.

Zeolite Pricing

Zeolite is a natural or synthetic mineral. It is known for its ability to adsorb gases and liquids. The cost of Zeolite can vary based on several factors:

- Purity: Higher purity Zeolite costs more.

- Type: Natural Zeolite is generally cheaper than synthetic Zeolite.

- Quantity: Bulk purchases often come with discounts.

Here is a basic comparison of Zeolite pricing:

| Type | Price per kg |

|---|---|

| Natural Zeolite | $2 – $5 |

| Synthetic Zeolite | $10 – $20 |

Overall, Zeolite can be cost-effective, especially in large quantities. But synthetic variants can be more expensive due to their higher performance and purity.

Silica Gel Pricing

Silica Gel is a porous, granular form of silicon dioxide. It is commonly used for moisture control. The cost of Silica Gel depends on the following factors:

- Bead size: Smaller beads usually cost more.

- Color indicating: Color-changing types are more expensive.

- Quantity: Buying in bulk reduces the price per unit.

Here is a basic comparison of Silica Gel pricing:

| Type | Price per kg |

|---|---|

| Regular Silica Gel | $5 – $10 |

| Color Indicating Silica Gel | $15 – $25 |

Silica Gel tends to be more expensive than natural Zeolite. But it offers specific benefits like moisture indication which can be crucial for some applications.

Credit: www.jalonzeolite.com

Frequently Asked Questions

What Are Zeolite And Silica Gel?

Zeolite and silica gel are desiccants. They absorb moisture from the air. Zeolite is a natural mineral. Silica gel is a synthetic material.

How Do Zeolite And Silica Gel Work?

Zeolite traps moisture in its porous structure. Silica gel absorbs moisture through its tiny pores. Both reduce humidity effectively.

Which Is Better, Zeolite Or Silica Gel?

Zeolite is better for long-term moisture control. Silica gel is ideal for short-term use. Your choice depends on your needs.

Are Zeolite And Silica Gel Reusable?

Yes, both are reusable. Zeolite can be regenerated by heating. Silica gel can be dried out and reused.

Conclusion

Choosing between zeolite and silica gel depends on your specific needs. Both offer effective moisture control. Zeolite is reusable and eco-friendly. Silica gel is more affordable and widely available. Understand your requirements and budget. This will guide your decision. Both have strengths and can serve different purposes.

Always consider the application and environment. Make an informed choice for optimal results. Your specific use case will determine the best option. Both materials serve well in their unique ways.